About Huatai

Expert in high-performance mold and parts solutions

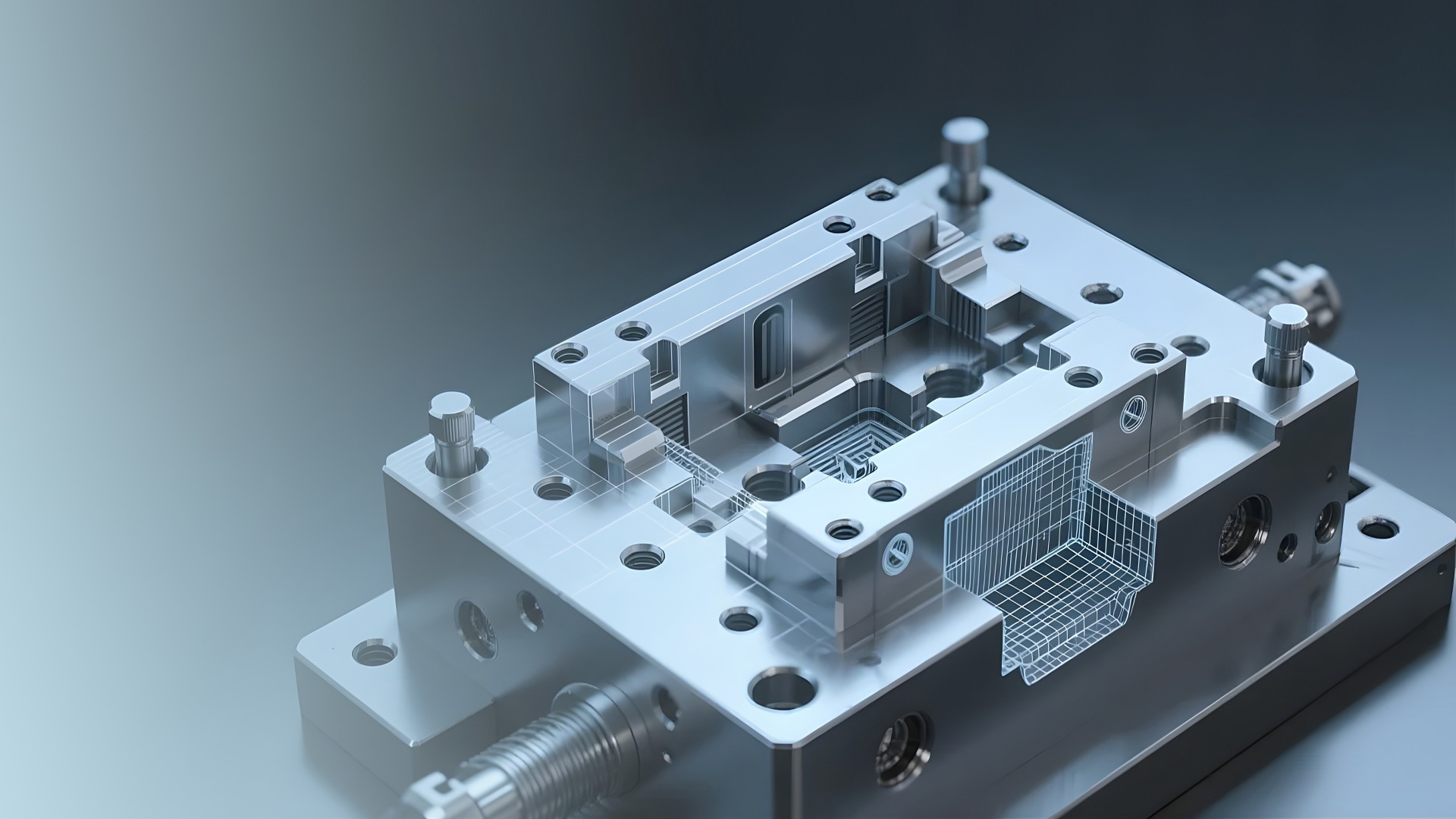

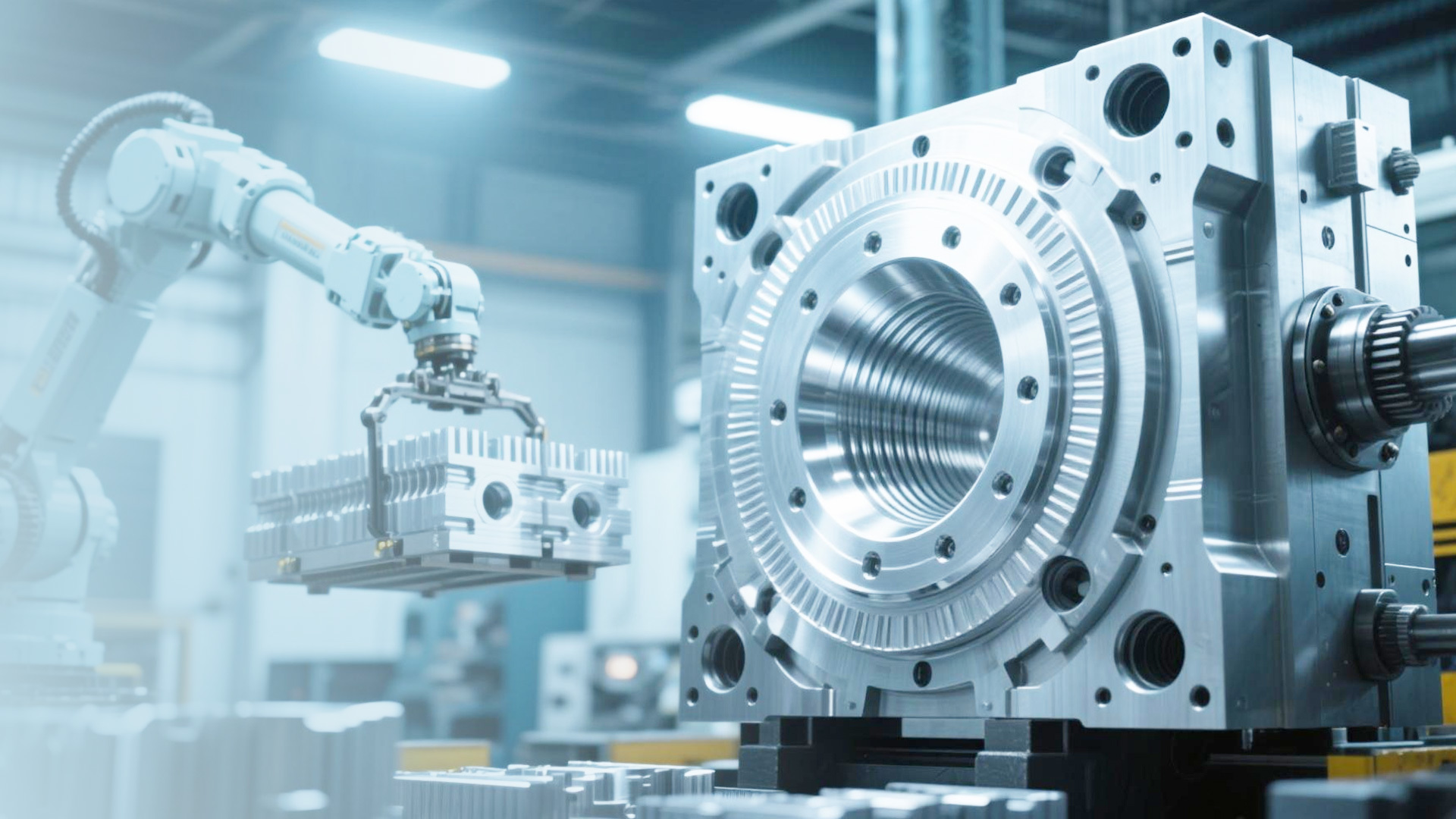

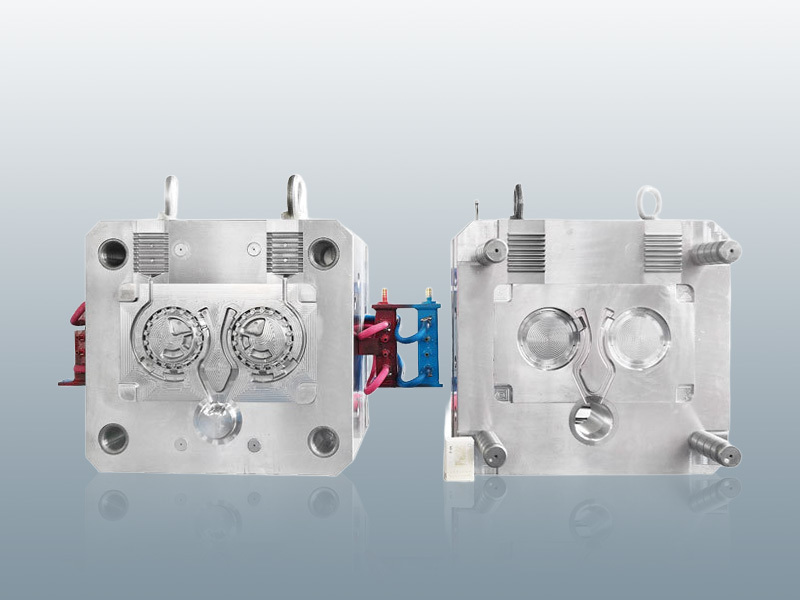

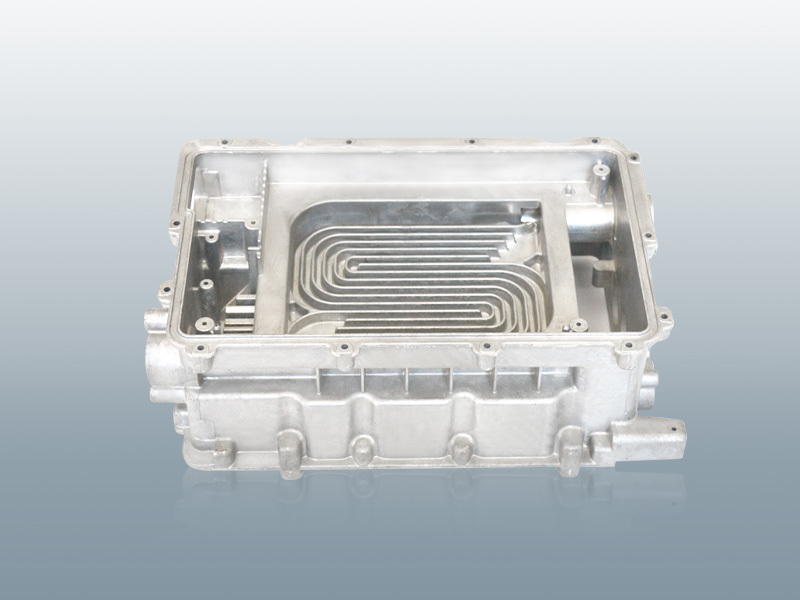

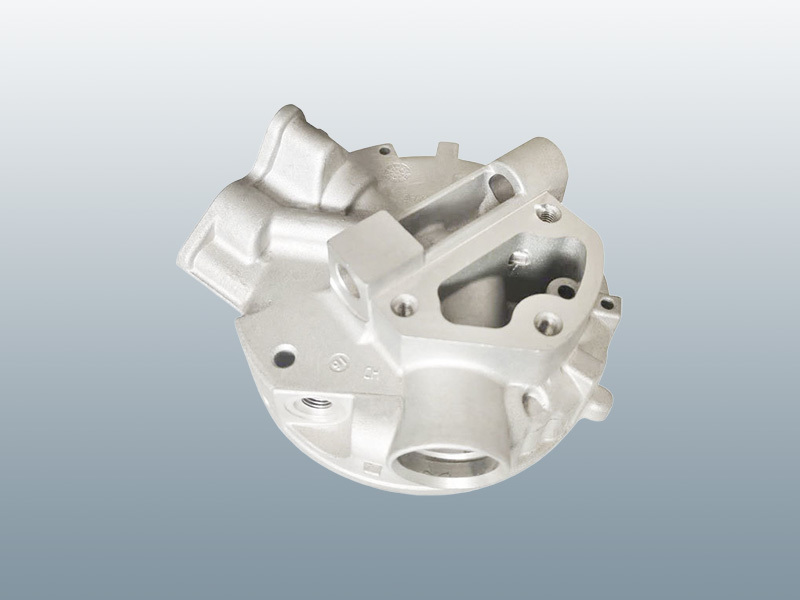

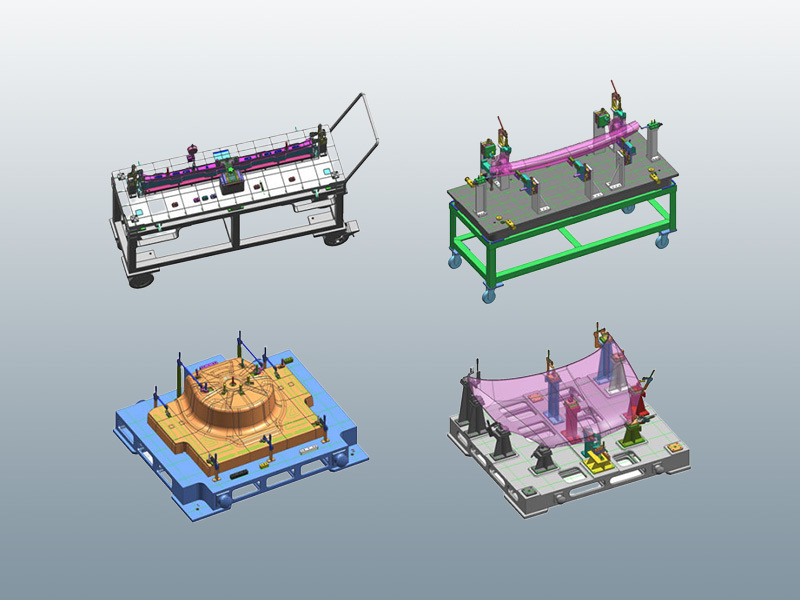

Huatai Mould ( Shenyang ) Co., Ltd. was established in 2007. It is mainly engaged in the research, development, design and manufacturing of die-casting molds and related mold accessories, tooling fixtures, and jigs for the automotive and electronics industries, as well as zinc and aluminum alloy automotive precision parts. The company is located in the Shenyang Economic and Technological Development Zone, Liaoning Province, adjacent to Dalian Port and the Beijing-Shenyang Expressway, with convenient transportation. The company has passed the IATF16949 quality management system certification. There are more than 300 employees, including more than 40 core personnel in design and R&D, with more than 10 years of experience in mold design and manufacturing, die casting, and machining, and can provide superior product technical support and services.

Founded in 2007

Number of Employees

Floor Area

Partners

Product Category

Blog

Expert in high-performance mold and parts solutions

04

2025